Fanlybond A2 Core

Introduction

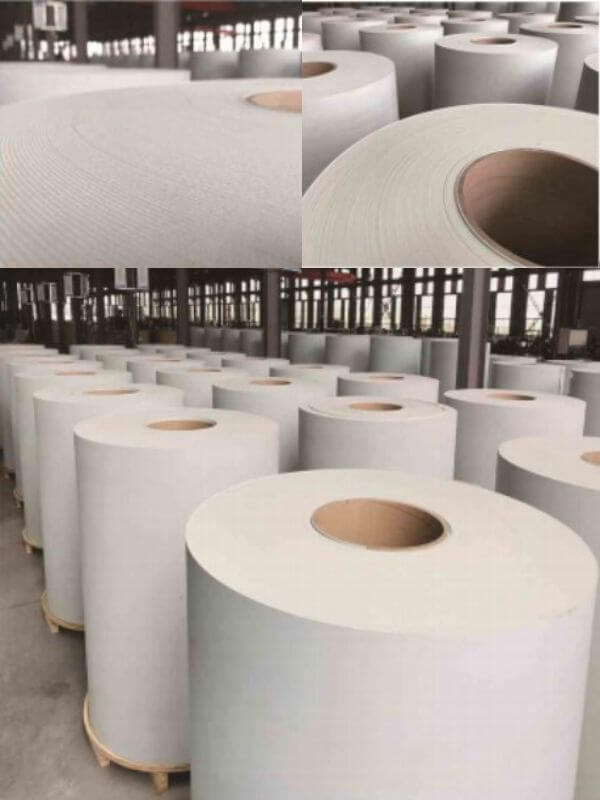

Fanlybond Grade A2 FR CMR adopts our company’s independent research and development equipment, uses inorganic materials, and is rolled and formed through special processes. Our A2 grade fireproof core roll has excellent flexibility, high fireproof performance, and it is environmentally friendly, smoke-free, and non-toxic. It can be used in the A2 grade fireproof aluminum composite panel production line to produce A2 grade fireproof aluminum composite panels.

Thickness range: 2-5mm

Maximum width: 2000mm

Density: 1.8-2.0 g/cubic centimeters

Weight: approx. 5.4kg/m² (Thickness: 3mm)

PCS(MJ/kg)<3 (according to EN13501-1)

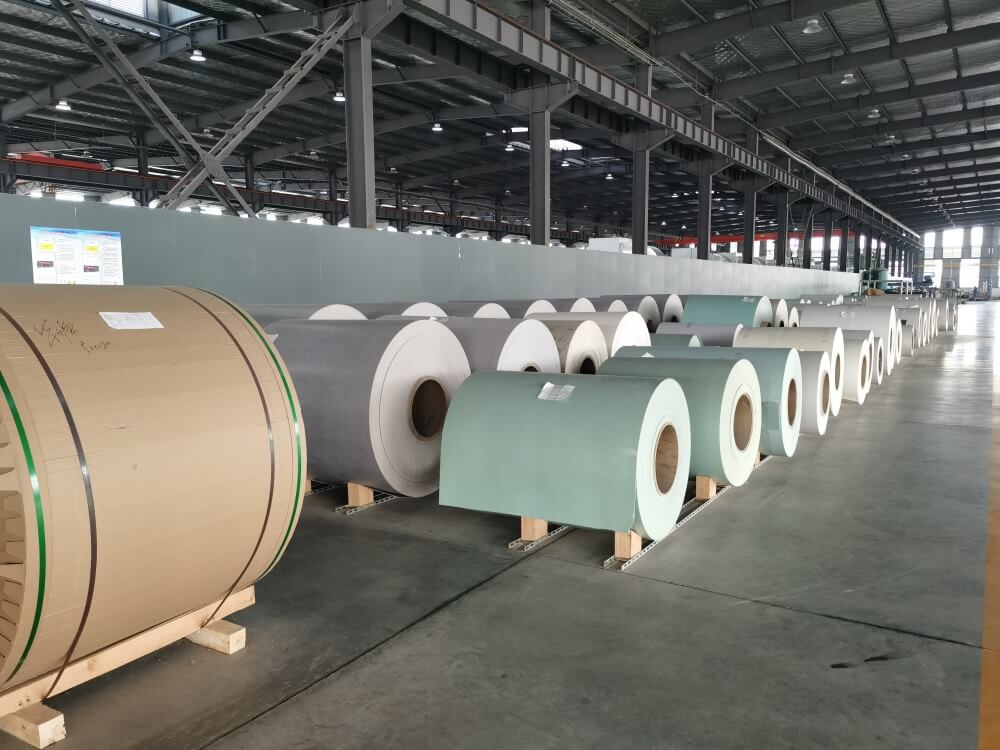

Color: white, green

Length: about 330m/roll

Tolerance: Width: ±1mm/Thickness: ±0.1mm

Production process

Grade A2 fireproof core coiled material is a new type of fireproof material with inorganic materials as the main component.

Its main form is a sheet core board with a specific width and thickness, which is rolled into a roll through a specific rolling device.

Because its performance reaches the A2 level fire protection standard specified in the national GB8624-2012 “Combustion Performance Classification of Building Materials and Products”, it is called a grade A2 fireproof core coiled material.

All process parameters of the production line are integrated and controlled, using visual window operations. All parameter settings, including temperature, speed, tension adjustment, etc., are integrated, with a high level of automation, intelligence, and informatization.

A2Powder➜ Mixing➜ Feeding➜ Forming➜ Baking➜ Precise Thickness Control System ➜ A2 Core

Product Parameter Introduction

Grade A2 fireproof core coiled material is mainly composed of special formulas such as “inorganic powder and environmentally friendly adhesive”. Such a formulation achieves its flexibility and bendability, allowing it to be made into rolls.

Its characteristics are “non-flammability, lightweight and high strength, excellent environmental adaptability and weather resistance”;

It is compounded with aluminum, steel, copper, titanium zinc, and other plates to make grade A2 fireproof metal composite panels.

This product has obtained 4 national invention patents and 1 PCT international invention patent.

Grade A2 fireproof core coiled material requires ≥96% inorganic materials and is laminated with an adhesive film.

Thickness range: 2-5mm; tolerance: ±0.1mm

Maximum width: 2000mm; tolerance: ±0.1mm

Indicator name |

Standard requirement |

Measured indicators |

Basis for inspection |

|---|---|---|---|

|

Total calorific value (PCS)/Core material MJ/kg |

≤3.0 |

1.4 |

GB/T 14402-2007 |

|

Total calorific value (PCS)/polymer membrane MJ/㎡ |

≤4.0 |

3 |

GB/T 14402-2007 |

|

Total calorific value (PCS)/Overall product MJ/kg |

≤3.0 |

2 |

GB/T 14402-2007 |

|

(FIGRA) W/S |

≤120 |

30 |

GB/T 20284-2006 |

|

(THR600s)MJ |

≤7.5 |

2.8 |

GB/T 20284-2006 |

|

(LFS)m |

Smaller than the edge of the specimen |

Smaller than the edge of the specimen |

GB/T 20284-2006 |

|

(SMOGRA)㎡/s |

≤30 |

0 |

GB/T 20284-2006 |

|

(TSP600s)㎡ |

≤50 |

20 |

GB/T 20284-2006 |

|

Burning drippings/particles |

No burning droplets/particles within 600s |

No burning droplets/particles within 600s |

GB/T 20284-2006 |

|

Smoke-producing toxicity level |

ZA1 |

ZA1 |

GB/T 20284-2006 |

|

Roller peel strength |

Average value≥110Nmm/mm,minimum value≥100Nmm/mm |

Average value140,minimum value120 |

GB/T 17748-2016 |

|

Hot water resistance (90℃6H) |

Peel strength reduction rate ≤ 25% |

20% |

JC/T 2561-2020 |

|

Water absorption(72H) |

≤6% |

≤4% |

JC/T 2561-2020 |

|

Tensile Strength |

≥4MPa |

4.5 |

JC/T 2561-2020 |

The products have passed the combustion test of the authoritative organization

NFPA285 Test: Sample Beginning of this test Testing agency: Thomas Bell-Wright Dubai International Consulting Company, United Arab Emirates

EN-13501-1 Test: Flame Test Approximately 10 minutes after the test begins. Testing agency: APPPLUS Spain

ASTME84 test: Photo sample after test located near the exhaust end Testing agency: ThomasBell-WrightInternational Consultants. Dubai, United Arab Emirates.

ASTM D1929 test: typical sample ignition details Testing agency: ATIIntertek-USA

BS 476.7 Test Testing agency: PSB Singapore

Application Advantages

- Green and environmentally friendly: Inorganic core material, environmentally friendly and energy-saving, reducing energy loss.

Fire safety: Ultra-high fire safety performance, combustion performance reaches non-combustible A (A2s1,d0,t0) level.

Any size: Size cutting adjustable , suitable for large sheet and panels, and easy to process and shape.

Extremely smooth: The core material and the panel shrink at the same time, making it extremely smooth and eliminating bulges.

Lightweight and durable: Sound and heat insulation, lightweight, and super weather-resistant, lasting as long as the building

Rich effects: Rich decorative effects, no obvious color difference, any color choice

Comparative Advantage

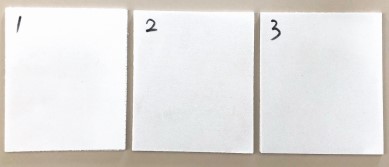

Flatness

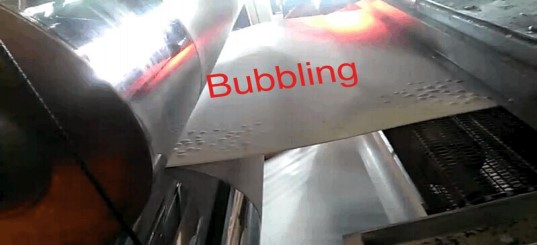

Other brands: many bubbles and dents.

Fanlybond: Absolutely smooth and delicate texture, ensuring ACP fit.

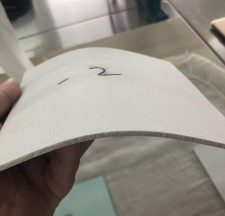

Flexibility

Other brands: prone to breakage.

Fanlybond: Can withstand greater bending.

Water Absorption

A2 core material immersion test for 72 hours.———–Fanlybong core material water absorption ≤ 4%.

Size: 100*100mm cutting without adhesive film.

The weight at the temperature of 90℃±2℃ is 72.0 g.

Soak for 72 hours.

Weight after immersion is 72.9 g.

Water absorption rate of core materials of other brands

Item |

Original Weight |

24H soaking Weight |

Weight increment |

Water Absorption |

48H soaking Weight |

Weight increment |

Water Absorption |

72H soaking Weight |

Weight increment |

Water Absorption |

|---|---|---|---|---|---|---|---|---|---|---|

|

Green1 |

138 |

145.5 |

7.5 |

5.43% |

146.6 |

8.6 |

6.23% |

149.4 |

11.4 |

8.26% |

|

Green2 |

135.1 |

142.8 |

7.7 |

5.70% |

143.8 |

8.7 |

6.44% |

146.4 |

11.3 |

8.36% |

|

White1 |

119.1 |

127 |

7.9 |

6.63% |

128.1 |

9 |

7.56% |

130.9 |

11.8 |

9.91% |

|

White2 |

119.2 |

126.7 |

7.5 |

6.29% |

128 |

8.8 |

7.38% |

130.5 |

11.5 |

9.65% |

Fanlybond Core material water absorption rate

Item |

Original Weight |

24H soaking Weight |

Weight increment |

Water Absorption |

48H soaking Weight |

Weight increment |

Water Absorption |

72H soaking Weight |

Weight increment |

Water Absorption |

|---|---|---|---|---|---|---|---|---|---|---|

|

051504-1 |

136.5 |

139.8 |

3.3 |

2.42% |

140.3 |

3.8 |

2.78% |

141 |

4.5 |

3.30% |

|

2 |

136.6 |

139.9 |

3.3 |

2.42% |

140.6 |

4 |

2.93% |

141.1 |

4.5 |

3.29% |

|

3 |

137.4 |

140.8 |

3.4 |

2.47% |

141.4 |

4 |

2.91% |

142 |

4.6 |

3.35% |

|

051601-1 |

133.9 |

137.2 |

3.3 |

2.46% |

138 |

4.1 |

3.06% |

138.7 |

4.8 |

3.58% |

|

2 |

135.7 |

139.4 |

3.7 |

2.73% |

139.8 |

4.1 |

3.02% |

140.5 |

4.8 |

3.54% |

|

3 |

133.9 |

137.4 |

3.5 |

2.61% |

138 |

4.1 |

3.06% |

138.7 |

4.8 |

3.58% |

|

051602-1 |

136.4 |

140 |

3.6 |

2.64% |

140.6 |

4.2 |

3.08% |

140.9 |

4.5 |

3.30% |

|

2 |

139.6 |

143.1 |

3.5 |

2.51% |

143.8 |

4.2 |

3.01% |

144.3 |

4.7 |

3.37% |

|

3 |

136.9 |

140.5 |

3.6 |

2.63% |

141.2 |

4.3 |

3.14% |

141.8 |

4.9 |

3.58% |

|

051603-1 |

134 |

137.5 |

3.5 |

2.61% |

138.3 |

4.3 |

3.21% |

139 |

5 |

3.73% |

|

2 |

132.9 |

136.4 |

3.5 |

2.63% |

137.2 |

4.3 |

3.24% |

137.9 |

5 |

3.76% |

|

3 |

133.9 |

137.2 |

3.3 |

2.46% |

138 |

4.1 |

3.06% |

138.6 |

4.7 |

3.51% |

|

051604-1 |

132.9 |

136.3 |

3.4 |

2.56% |

137.1 |

4.2 |

3.16% |

137.6 |

4.7 |

3.54% |

|

2 |

135.2 |

138.8 |

3.6 |

2.66% |

139.6 |

4.4 |

3.25% |

140.2 |

5 |

3.70% |

|

3 |

134.2 |

138.9 |

4.7 |

3.50% |

138.4 |

4.2 |

3.13% |

139 |

4.8 |

3.58% |

The adverse effects of core material water absorption exceeding 6%

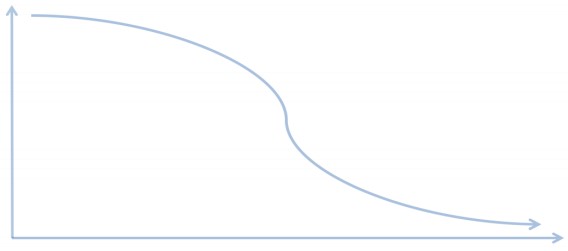

Relationship between water absorption and peel strength

If the water absorption rate exceeds 6%, it will cause the delamination peel strength of the core material to decrease over time.

Easy to bulge during lamination

Performance comparison of core materials after soaking

Other brands: The core material is very brittle, soft and easy to collapse.

Fanlybond: Basically no change

Packing

Compared with sheet boards, roll core boards are a major innovation and are easy to transport. After packaging, it is provided to customers, and the composite line can be used directly for composite processing to make boards, which solves the problem of site restrictions. It is more conducive to the large-scale promotion and application of this product.

Certification

The quality of this product can be tested by the following official organizations and reach the international leading level.